We are living in a fast-paced era. Information is available at the tip of your fingers, kudos to the Internet. Be it information or your favorite pasta, it all comes at a whirlwind speed. So, what did we observe here, we all want things to be done at a faster pace? Yes. Then, why delay in switching to power tools that can boost your business & yield better results. In today’s section, we are trying to do our best to help you in selecting the correct power tool for your job. So, let’s barge in: How to choose power tools?

Need for Power Tools

It is a golden rule to know WHY DO WE NEED before buying! Don’t you agree? Before the invention of machines, all manual jobs consumed both time and energy. As time flew by, and great inventors & scientists made inventions that helped mankind. In these courses of action, the tools were never left behind. Today we can see how machines can cut blocks of ceramic tiles or a big timber in just a fewer minutes. Now, let us see what power tools can do for us.

- Long man-hours for tedious jobs can be drastically cut-down

- From Days to Hours or Hours to Minutes or Minutes to Seconds – new time frame is set to complete a job

- Easy handling, portable, ergonomically designed tools create a better working atmosphere

If you see the above 3 statements, it is clear that time & effort are being considered or say emphasized. It means that even today we appreciate those two factors. Profit & Customer Satisfaction is all that matter at the end of the day. And power tools provide full justice to these business set goals.

Criteria for selecting power tools

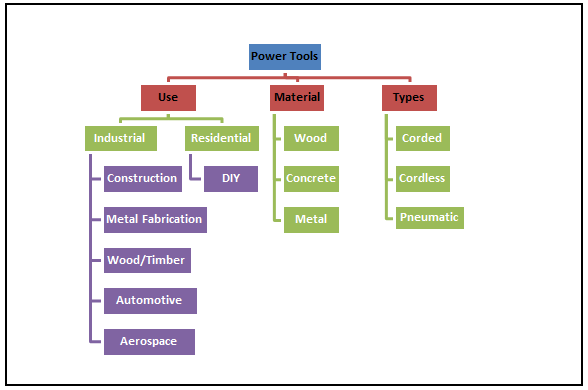

Now that we know the importance of these electric tools, we can further narrow down our discussion. Many factors influence the selection criteria for a power tool.

- Is it for industrial or residential use?

- Which material are you using – wood, concrete, metal, plastic, glass?

- What type of job are you doing – cutting, grinding, fastening screws, ripping wood or mixing concrete?

These questions lead you straight towards activities or the job that you want to carry out. But other factors also play a vital role in picking these tools.

- Productivity – Which tool matches the desired overall throughput rate?

- Ergonomics – Is the tool causing extra muscular pressure?

- Reliability – Can I extract accurate work?

- Durability- Wear and tear conditions

- Quality- Do they last for a good period?

- Cost – Are they economical, do they fit into the budget?

Productivity: You can expect 100% productivity from these tools. As they are powered by electricity or battery or pressured air, you can always expect a quick job. To understand better; you can ask the sales representative to perform a demo at your workplace. Give him/her a piece of wood and see how fast the tool rips or cuts off the wood.

Ergonomics: Manual work is always tiresome and painful. No wonder why everyone looks for a machine to perform jobs/tasks. And when you have them, it is wise to pick them up quickly. If you see these electric tools, they are handy and easy to perform the actions. Say you want to fasten a bolt or a nut to fix the broken window sill. Use the Impact Drill. You will no longer complain about elbow or shoulder pain. All these tools are well-designed to handle such situations.

Reliability: Accuracy, Consistency & Precision - all can be achieved. As these tools are used for repetitive work, they never fail to perform.

Durability & Quality: We all agree these two factors can go hand-in-hand. It purely depends on the usage type. Never rough-handle or over-use them. Well-maintained tools do last for a pretty good time.

Cost: More or less, these tools are for one-time investment. They are affordable. Even if you fall into the category of DIY; you can still go for them.

Now, let’s get into the technical part. As these tools are used by the technicians; they always look for product specifications & features. You cannot rule them out while selecting the tools. Every manufacturer provides these technical details either in the form of a brochure or as a manual. Some of the details that we usually see are listed here that help in making a better decision.

- Make & Model

- Speed & Power

- Motor

- Weight

- Battery

- Cutting depth & action

- Operating mode – auto, standard

- Attached accessories

Classification of Power Tools – Type, Name & Use

As we move ahead, it is good to know a few tools that are commonly used in both industrial & residential activities. You have tools with & without cords, pneumatic types. Cordless tools are a priority for DIY users. Some of the popular tools are Angle Grinder, Cordless Power Drill, & Hammer Drill.

Corded: Drilling, Polishing, Compressors, Fastening, Grinding, Heat Gun, Wrench, Sanding, Hammers, Vacuum Cleaners, Blower, Mixers, Sawing, Vibrator, & Milling

Cordless: Screwing, Drilling/Hammering, Drilling/Screwing, Sawing, Milling, Grinding, Rotary Hammer, Blower, Wrench

Pneumatic: Grinding, Wrench, Polishing, Hammering, Screwing, Drilling, Sawing

DIY Tools: For most woodworking or gardening activities, these tools play along well. Hedge Trimmer, Blower, Grass Trimmer, Grass Shear, Brush Cutter, Sprayer, and Lawnmower are the classic tools for gardening. While if you are an avid woodworker, then go for Drilling/Hammering, Screwing, Sanders, and Drilling/Screwing tools.

We have finally arrived at our last segment. Yes, let’s conclude by selecting the right tools that go well with your job & requirements. We are glad to bring you this preliminary, yet detailed power tool list selection clause. It would be better to write down your activities, requirements, and budget, and then make a checklist to buy these tools. Also, try to maintain a time chart for each job with your current conventional tools. Analyze the time taken to complete the job. Adjust the job slots with power tools; so that manpower can be well allocated. Remember, tools can assist us in doing a better job. They are worth buying.

.png)